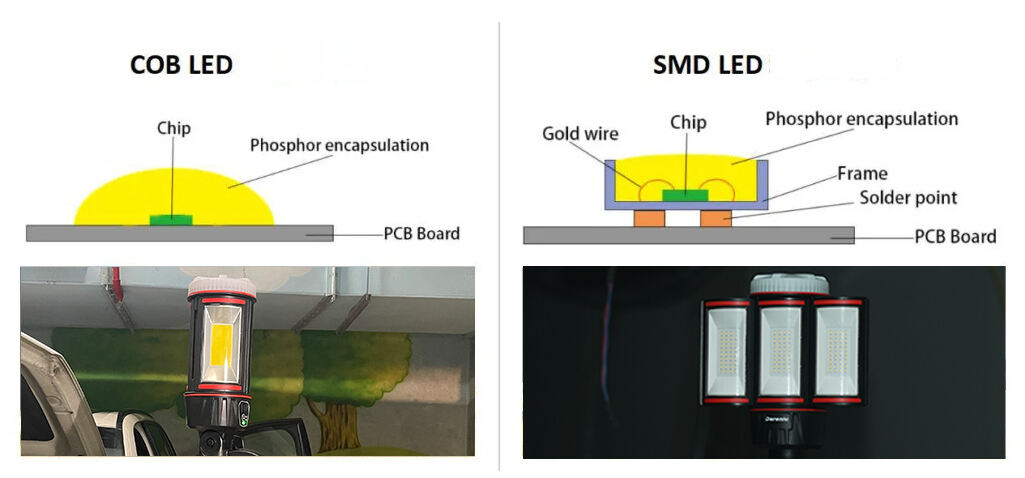

COB(Chip on Board) and SMD (Surface Mounted Device) are two common ways to make LED lights.Both are used in many kinds of lights, but they are different in how they are made, how the light looks, and where they are used.

What is COB?

COB (Chip on Board) means many small LED chips are placed directly on a metal board and covered with a layer of yellow glue. They work together as one big light source. COB lights are very bright and are often used in floodlights, factory lights, and car lights.

What is SMD?

SMD (Surface Mounted Device) means each LED chip is made into a small lamp bead. These beads are placed one by one on a circuit board. SMD lights are easy to fix and are used in light strips, bulbs, ceiling lights, and home or office lighting.

Key Differences Between COB and SMD

| Feature | COB | SMD |

| Packaging | Multiple chips integrated as one unit | Single chip packaged per unit |

| Light Surface | Uniform, broad light source | Spotty light source, visible dots |

| Heat Dissipation | Better, direct contact with substrate | Slightly weaker, through lamp bead |

| Cost & Maintenance | Higher cost, not easy to repair | Lower cost, easy to replace |

| Applications | Flood lights, high bay lights, car lights | Light strips, bulbs, ceiling lights |

Conclusion

If you need high brightness, focused illumination, and care about thermal performance and uniform lighting, COB is the better choice. If you are looking for cost-effective, flexible lighting with easier maintenance, SMD is more suitable.

What We Offer---Custom LED Chips for Work Lights

At Daren, we have over 20 years of experience in making work lights. We know LED chips very well and can meet most custom needs.

Custom:

· Adjust color temperature, CRI, and power

· Use famous LED brands like Cree, Osram, and Samsung etc.

We also have LED Life Aging Test Equipment in our factory to check the quality of the LED chips.

If you need custom LED chips for your work lights, we are ready to help.

Contact us to learn more about our custom LED options.